Carbon Footprint and Stage V Engines

Technology and Sustainability Working Together

The heart is green, but the mind makes the difference

On construction sites, in fields, during emergencies—where strength and reliability are essential—diesel engines remain indispensable.

Today, the real challenge is not just keeping them running: it’s making them work better, consume less, and minimize pollution.

This is where Stage V engines come in—the “green” evolution of mechanical power.

With advanced exhaust filtration and treatment systems, Stage V engines meet the strictest European standards for non-road engines.

The result? A drastic reduction in particulate matter, nitrogen oxides, and other harmful emissions.

🚜 The Reality on the Field: Stage V Engines’ Potential and Challenges

Anyone working in fields or on sites knows that Stage V engines are not without practical issues.

Particulate filters (DPF) can clog in dusty environments, frequent regenerations are needed, electronics are more complex, and maintenance costs are higher—real concerns for many operators.

However, these challenges do not stem from the engine itself, but from how it is managed.

A Stage V engine, if intelligently controlled, can deliver stable performance and lower fuel consumption, maintaining the reliability farmers require.

This is where the added value of our solutions comes into play.

🎛 IdroMOP’s Contribution: ECUs That Make a Difference

At IdroMOP, we don’t just make engines run: we make them work intelligently.

Our electronic control units (ECUs) for Stage V engine-driven pumps improve efficiency and reduce environmental impact in multiple ways:

- Optimize operating cycles, avoiding unnecessary revs or inefficient regimes.

- Adjust engine power to real working conditions, preventing overloads or underuse.

- Activate automatic start-stop logic, reducing idle fuel consumption.

- Monitor fuel usage in real time, enabling precise analysis and corrective action.

- Support predictive maintenance, preventing DPF clogs or performance drops.

In practice, the ECU doesn’t just control the engine—it helps it last longer and consume less, reducing the issues that often discourage farmers from adopting Stage V engines.

💰 Lower Consumption, Lower Maintenance, Higher Savings

Sustainability is not just an environmental concept—it’s also a matter of economic convenience.

An optimized engine consumes less diesel, reduces extraordinary maintenance interventions, and keeps performance consistent over time.

The numbers speak for themselves:

- Up to 15–20% fuel savings, equal to over €2,000 per year on a pump consuming 10,000 liters of diesel annually.

- Fewer forced regenerations and clogs, meaning less downtime.

- Longer engine and filter life thanks to more balanced load management.

- Every liter of diesel saved means 2.6 kg less CO₂ in the atmosphere—and lower costs at the end of the season.

🌍 Carbon Footprint: Understanding and Reducing Impact

The carbon footprint measures the total greenhouse gas emissions, mainly CO₂, from an activity. For diesel pumps, the main source is fuel consumption: each liter burned produces about 2.6 kg of CO₂.

But it’s not just abstract numbers: an unoptimized engine can accumulate unnecessary emissions through prolonged idle, frequent regenerations, or wasteful operating regimes.

In practice, intelligent management not only reduces the carbon footprint but also turns energy savings into tangible economic benefits—a double win for farmers and businesses.

🌱 Sustainability You Can See Every Day

Our ECUs are already operational in dozens of systems that:

- Irrigate fields while reducing water and fuel waste.

- Control remote systems in isolated areas.

- Support firefighting and emergency drainage, where every minute counts.

Farmers and operators using them report fewer issues, greater autonomy, and more peace of mind in daily work.

🧠 Behind Every Engine, a Smart Mind is Needed

Whether it’s a modern Stage V engine, a previous-generation motor, or a custom solution for special applications, the engine is the heart: it provides strength, energy, and motion.

But even the most powerful heart needs a mind capable of making it work at its best.

Our ECU is that mind.

It optimizes performance, reduces fuel consumption, simplifies management, and enhances every beat—under any working condition.

This is why IdroMOP is the right choice for the entire value chain: it makes every heart pump at its best, from traditional to advanced engines, transforming power into efficiency, sustainability, and reliable performance in the field.

📩 Want to Learn More?

Contact us for a technical brochure or a tailored consultation.

Together, we can reduce your carbon footprint—and your operational costs—one pump at a time.

References

- Regulation (EU) 2016/1628 – Requirements for gaseous and particulate emissions from non-road engines.

- ICCT – Managing Emissions from Non-Road Vehicles – Report on controlling emissions from non-road vehicles.

- DieselNet – Emission Standards: Europe: Nonroad Engines – Detailed overview of Stage V limits.

- Construction Equipment Association (CECE) – Exhaust Emissions – Context on non-road engines in Europe.

- CodeReady – Vehicle Emissions Standards – Comparative chart of US/EU Tier & Stage standards.

- ATS-Group – Approval of Non-Road Engines (NRMM) – Explanation of regulations for agricultural and construction engines.

- Econologia – CO₂ Emissions per Liter of Fuel

- Abitcoop – Greenhouse Gas Emissions: Indicative CO₂ Values

- Technical Legislation Bulletin – Main Fuel Emission Factors

- MICHELIN Connected Fleet – Calculating Fleet Carbon Footprint

- Encyclopedia MDPI – European Air Pollution Restrictions on Internal Combustion Engines

More articles

ELECTRIC MACHINE

A solution that combines sustainability and technology in a single machine. Power and efficiency for increasingly environmentally friendly irrigation.

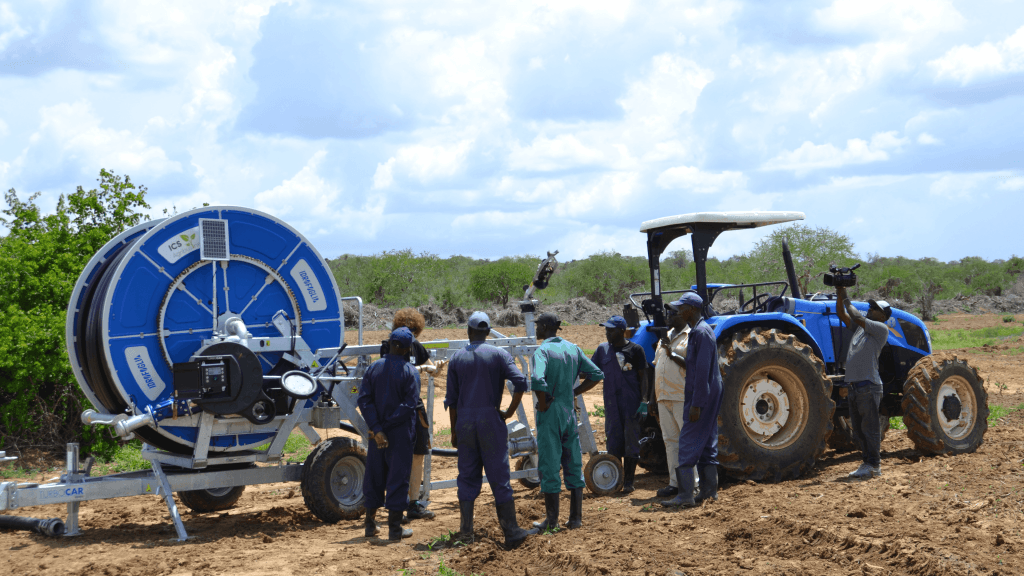

KENYA

An initiative under the banner of innovation and sustainability, for a future of growth and development for the community!

SMART IRRIGATION

The digitization of agriculture. Optimize water use, improve agricultural productivity and promote sustainability.

FIREFIGHTERS

Advanced technology to deal with any emergency effectively and safely.

SCRAPPING PLAN

2G and 3G networks are disappearing. Upgrade your devices to the new 4G and 5G networks and ensure a faster, more secure and reliable connection!

EVERY DROP COUNTS

Only 3 percent of the water is unsalted, and 2.5 percent of it is found in glaciers. Rimane perciò solamente lo 0,5% di acqua disponibile per l’uomo e per l’ecosistema. L’agricoltura impiega in media il 70% dell’acqua dolce, di cui più della metà viene utilizzata per irrigare.

BRAND IDENTITY

The brand identity conveys innovation, reliability, growth and sustainability through the use of colors that evoke professionalism and commitment to a greener, more technological future. The bright, modern hues reflect innovation, creating a strong, recognizable image that represents the company’s core values.

AGRITECHNICA 23

Learn about the technologies on display at the Agritechnica 2023 trade fair